1. Brief introduction of computer controlled scaffold fastener testing machine:

1. WDW- J 150 computer-controlled scaffold fastener testing machine is an electronic universal testing machinespecially designed for steel pipe scaffold fasteners. It is suitable for universities, research institutes , quality inspection and testing units .

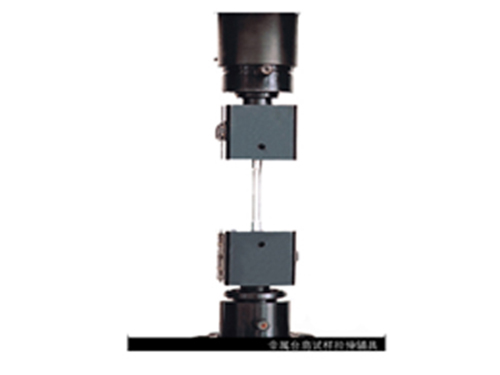

2. The computer system controls the rotation of the servo motor through the full digital controller and the speed control system. After the deceleration system is decelerated, the moving beam is driven up and down by the precision ball screw pair to complete the stretching, compression, bending and shearing of the sample In addition, it can beequipped with a wide range of test accessories. It has a very broad application prospect in the mechanical performance test of metals, non-metals, composite materials and products. 3. This machine is designed according to the test method of GB15831-2006 "Steel Pipe Scaffolding Fasteners". It can meet the anti-skid performance test, destructive performance test, torsional stiffness performance test, butt fastener tensile performance test, and base compression performance test of right-angle fasteners.

2. The main technical indicators of the microcomputer-controlled scaffold fastener testing machine:

1. Maximum test force: 150kN

2. Test force measurement range: 0.4%-100% (600N-100000N)

3. Test force indication accuracy: better than indication ±1%

4. Test power resolution: 1/300000 (the whole process is not divided into files or equivalent 6 files)

5. Measuring accuracy of beam displacement: resolution higher than 0.0025mm

6. Test speed range: 0.05—500mm/min, stepless speed regulation

7. The speed control accuracy: ±. 1% (0.01 - 10mm / min); ± 0.5% (10 - 500mm / min)

8. Constant force, constant deformation, constant displacement control range: 0.2%-100%FS

9. Constant force, constant deformation, constant displacement control accuracy:

Set value , when set value ≥10%FS, within ±0.1% of set value

10.Deformation rate control accuracy:

Speed , when the speed is ≥0.05%FS, it is within ±0.5% of the set value

11. Test space: A: Tension space: 700mm B: Compression space: 700mm

12. Fixture form:

1) Scaffolding anti-skid performance test device : 1 set (implement GB15831-2006) to meet the anti-skid performance test and anti-destructive performance test.

2) Scaffold torsion stiffness performance test device : 1 set (implement GB15831-2006) (with related protection device);

3) Tensile fixture : 1 set (meet the tensile performance test of butt fasteners)

4) Compression fixture : 1 set (meet the base compression performance test)

Attachment to GB/T24911-2010 "Test Method for Mechanical Properties of Bowl-buckle Steel Pipe Scaffolding Structure"

1. Upper bowl buckle tension resistance ( bowl buckle tension resistance) attachment ( test force P is added from 0KN to 15KN and then completely unloaded, and then added from 0KN to 30KN, this load is maintained for 2min, and no damage to each part)

2. Tensile resistance of upper bowl buckle ( bowl buckle welding strength) Attachment (test force P is added from 0KN to 30KN and then completely unloaded, and then added from 0KN to 60KN, this load is maintained for 2min, no damage to each part)

3. 3.1 Crossbar joint strength ( test force P is added from 0KN to 25KN and then completely unloaded, and then added from 0KN to 50KN, this load is maintained for 2min, and there is no damage to each part)

3.2 Welding strength of crossbar joint ( test force P is completely unloaded after adding from 0KN to 10KN, and then adding from 0KN to 25KN, this load is maintained for 2min, no damage to each part)

4. Bowl buckle adjustable support compressive strength attachment (test force P is added from 0KN to 50KN and then completely unloaded, and then added from 0KN to 100KN, this load is maintained for 2min, no damage to each part)

13. Power supply of the whole machine: single-phase 380V±10%, 50Hz

14. Host size: 760×520×2000mm

1 5. Weight: 800 : kg