1. Overview of the microcomputer controlled self-locking nut locking performance testing machine

1. Purpose

XZW-series microcomputer-controlled self-locking nut locking performance testing machine is mainly used to detect the locking performance test of self-locking nuts. The loading speed is automatically controlled by the microcomputer. The AC control motor and its driver are used to automatically detect the number of locking times and torque. Record test curves, etc. It is widely used in the detection of the locking performance of self-locking nuts by manufacturing and using departments of factories and mining enterprises, aerospace, military industry, scientific research institutes, etc.

2. Applicable standards

1) JB/T9370—2007 "Technical Conditions for Torsion Testing Machines"

2) GB/T3098.9-2010 "Effective torque steel lock nuts for mechanical properties of fasteners"

3) GB/T16823.3-2010 "Fastener Torque-Clamping Force Test"

4) GB943-88 "Self-locking Nut Technical Conditions"

5) GB/T3098.9-2002, HB5643-87/HB7596-98 "Self-locking Nut Test Requirements and Methods"

6) The user can provide relevant technical standards, and realize the control of the test method and related data collection and processing according to the standards provided by the user.

2. Features of the microcomputer controlled self-locking nut locking performance testing machine

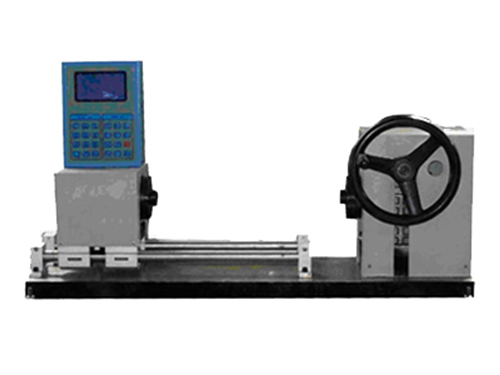

1. Main machine: adopts horizontal structure, precision planetary gear reducer, and uses rolling linear guide to make the moving end chuck move axially, so as to eliminate axial movement friction to the maximum extent.

2. Loading method: Adopt all-digital AC servo motor and driver to ensure the stability, uniformity and no impact of the loading speed.

3. The detection of torque and rotation angle: high-precision symmetrical torque sensor is used to eliminate the influence on the accuracy of the test results during forward and reverse rotation; high-precision photoelectric encoder is used for rotation angle detection.

4. Operation and display: There are two ways of manual adjustment and computer operation.

4.1 Computer operation and display part:

Based on Win Chinese operating platform, computer screen display, man-machine dialogue mode. The screen displays the test torque, rotation angle, test speed, test torque-angle curve, torque-time curve, rotation angle-time curve, working status of the testing machine, etc. With artificial intelligence programming function, you can set the test mode arbitrarily according to your test mode.

4.2. Manual adjustment part: with forward and reverse manual adjustment buttons, which are used for specimen clamping and adjustment before the start of the test.

4.3. Test method, data, curve record

1) Comply with the relevant provisions in GB943-88 "Self-locking Nut Technical Requirements" and HB5643-87/HB7596-98 "Self-locking Nut Test Requirements and Methods".

2) Data recording: Record the maximum torque (screw in) the first time the screw rod extends out of the locking part of the nut for three clicks, and record the first time the screw touches the locking part of the self-locking nut until the screw reveals the second click Maximum torque during the process (screw in). The minimum torque for the fifth time (customizable as needed), and the minimum torque for the fifteenth time (customizable as needed) (the remaining torque of the screw screw). The parameters (the number of buckles extending out of the locking part of the nut and the number of remaining buckles withdrawing from the nut) can be changed at will; it can also be set as the screw start to enter the nut locking part, that is, when the torque is greater than zero (the value can be set) starting point.

3) Curve record: record the curve of the first screw-in, the curve of the fifth screw-in and screw-out (customizable as needed) and the curve of the fifteenth screw-in and screw-out (customizable as needed), which can be enlarged , Label coordinates, etc.

Third, the main technical indicators of the microcomputer controlled self-locking nut locking performance testing machine:

1. Accurate torque measurement range: 2~100Nm

2. Torque resolution: ±1/300000

3. The minimum reading value of the rotation angle: 0.01 circle

4. Relative error of torque indication: ≤±1% within the measuring range (both forward and reverse rotation)

5. Relative error of torque indication repeatability: ≤1% within the measurement range

6. Loading speed of testing machine: 0.003r/min~30r/min

7. The distance between the two chucks: 0~250mm

8. Coaxiality error between two chucks: ≤Φ0.10mm

9. When the testing machine exceeds 5% to 10% of the rated torque, the testing machine will automatically stop (you can also set it yourself).

10. With over-voltage, over-current, over-speed, overload and other safety protection.

11. Power supply voltage: 220VAC±10% 50Hz

12. Host size: 1700×700×1200 (mm)