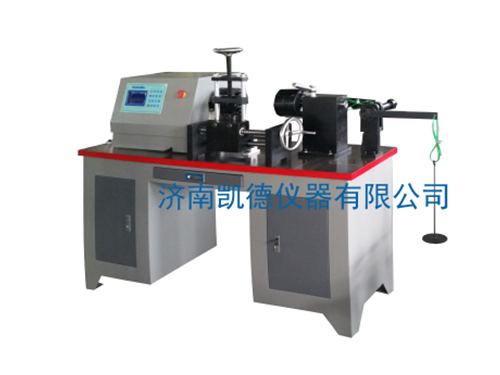

1. Overview of wire torsion winding test machine :

1. This machine is a dual-purpose machine, mainly used for testing the twisting and winding test of Ф3-Ф10mm metal wire , detecting the number of twisting turns and observing the surface defects of the material after winding.

2. The machine is a horizontal host, loaded by a motor, a rotation sensor detects the number of twisting turns, and the LCD screen displays the number of twisting turns and winding turns. The machine has two detection functions at the same time. The torsion test and the winding test do not interfere with each other and are relatively independent. It has the advantages of simple operation, convenient use, stable and reliable performance, and low cost.

3. This machine is dedicated to the production and use units of wire and cable, steel wire , copper wire or other wire materials, quality supervision, scientific research institutes, colleges and universities, iron and steel metallurgy and other units.

2. Applicable standards of wire torsion winding tester :

1. GB/T239.1-2012 "Metal Material Wire Part 1: Unidirectional Torsion Test Method"

2. GB/T239.2-2012 "Metal Material Wire Part 2: Two-way Torsion Test Method"

3. GB/T4909.4-2009 "Test Method for Bare Wire Part 4 Torsion Test"

4. GB/T4909.7-2009 "Test Method for Bare Wire Part 7 Winding Test"

3. Performance characteristics of wire torsion winding test machine :

1. Speed: meet the test requirements in accordance with the test standards;

2. Liquid crystal display: large liquid crystal display shows the number of test laps;

3. Lever weight afterburner: there is a 10:1 enlarged lever afterburner, which can produce no more than 2% of the axial tension during the torsion test;

4. Anti-collision function : due to the tensile force of the weight, after the sample is broken, there is an anti-collision spring to buffer and lock the impact;

5. Locking device : Loosen the screw to move the moving end freely along the guide rail, which is convenient for replacing core rods of different diameters (winding) and clamping wires of different diameters (twisting);

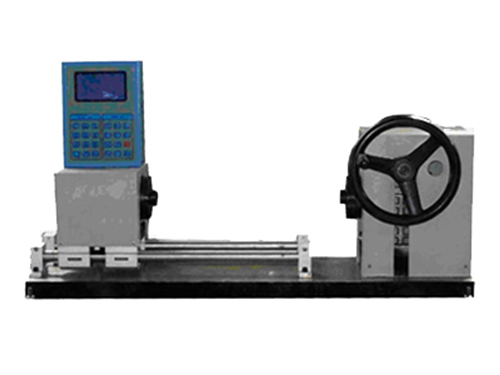

6. Winding guide device: A guide device is arranged along the winding direction, which is fixed on the ball screw rod that moves left and right, and the hand wheel rotates the screw rod to make the wire tightly wound around the mandrel;

7. Automatic shutdown function: Automatic shutdown after the test piece is broken, and the value of the test circle is automatically blocked;

4. Main technical parameters of wire torsion winding test machine :

1. Diameter range: Ф3-Ф10mm

2. Torsion winding speed: 10~30rpm, continuously adjustable

3. Fixture spacing: 0~500mm, adjustable

4. Fixture action: chuck type

5. Speed display: LCD screen digital display, adjustable

6. Counting range: 1-999999

7. Clamping method: manual

8. Mandrel diameter: according to customer requirements

9. Working voltage: AC 380V±10% 50Hz