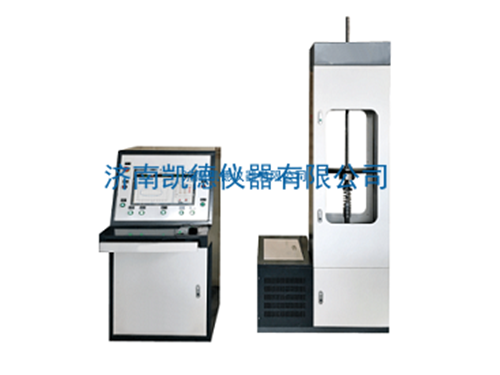

1. Overview of WDW-TH series microcomputer-controlled locomotive spring lateral stiffness testing machine

1. WDW-TH series microcomputer-controlled locomotive spring transverse stiffness testing machine is a spring load testing machine developed for locomotive spring manufacturers. In addition to the testing functions of conventional spring testing machines , it can also offset springs with transverse force. Test and confirm the direction and offset angle.

2. The test testing machine by a drive system, loading system, transmission system, measurement and control system, a display system, etc., all-digital AC servo motors and drives, precision planetary reducer, high efficiency synchronous belt without gaps and precision ball screw The bars constitute the transmission. Stable and reliable operation.

3. Function of WDW-TH series microcomputer controlled locomotive spring lateral stiffness testing machine

1) Conventional functions: multiple control modes such as force, displacement, and deformation:

a. Set the test force to detect the deformation of the spring. b. Set the amount of deformation and detect the test force of the spring. c. Set the test force to detect the remaining height of the spring. d. Set the remaining height of the spring and detect the test force of the spring; 2) General functions

a. According to different spring design requirements, enter the known parameters, and then the test can be automatically performed. After the test is completed, it will automatically return to the initial position of the test. If the batch test is carried out, it will show its powerful superiority. The user only needs to input the test parameters at one time to realize all the automatic operations in the experiment process except the replacement of the spring, with very high test efficiency.

b. The microcomputer-controlled spring lateral stiffness tester can complete the sensor's parameter calibration, zero-point clearing, parameter storage and loading and other functions; the controller has protection functions such as various test parameters exceeding limits, exceeding settings, automatic shutdown or alarming;

c. Under the operating system WindowsXP platform, full Chinese operation interface, friendly man-machine interface, all operations of the testing machine are completed by the computer keyboard and mouse, the computer screen displays the testing force, displacement, beam moving speed, testing machine working status, etc., and has Shortcut key operation. Real-time data collection, data calculation and processing, and provide data storage, query, printing and other functions, can display and draw test force-deformation curves in real time, can zoom in or out of the curve, zoom in part of the curve, and the user can pass in the zoomed area Drag the mouse to realize the translation of the magnified curve.

3) Lateral stiffness, lateral free bending deformation test function

a. Act the specified axial static force on the spring, measure the deformation and direction of the spring on the X, Y axis, and calculate the bending direction, offset and angle of the measuring platform;

b. The force with which the specified axial static force is applied to the spring, the measuring platform can return to its initial center position, that is, the bending force;

c. Apply the same amount of axial static force to the spring, continuously apply lateral force to the spring, measure the lateral force under the specified lateral displacement, calculate the lateral stiffness of the spring and draw the lateral stiffness-deformation curve of the spring.

2. WDW-TH series microcomputer controlled locomotive and rolling stock spring lateral stiffness testing machine meets the standards:

1. TB/T2211 -2010 "Steel Coil Spring for Suspension Device of Locomotive and Rolling Stock"

2. BS EN 13298 -2003 "Suspension spiral steel spring for railway installations"

3. TB/T2843 -2015 "General Technical Requirements for Rubber Elastic Components for Rolling Stock"

4. TB/T3268 -2011 "Railway Freight Car Saddle Rubber Pad"

5. TB/T3269 -2011 "Railway Freight Car Flexible Side Bearing"

3. Functions of WDW-TH series microcomputer-controlled locomotive spring lateral stiffness testing machine :

1. Spring and elastic element vertical (radial) load, vertical (radial) deformation, lateral load stiffness, lateral displacement test and research.

2. Test and confirm the axial stiffness, lateral stiffness, offset direction, and offset angle of springs with lateral force.

3. Locomotive suspension springs, railway large-diameter springs, high-speed EMU springs, high-speed passenger car V-shaped springs.

4. All kinds of spiral springs, valve springs, diaphragm springs, damping springs, disc springs, high temperature springs, circlips, extension springs, compression springs, scroll springs, heterosexual springs.

5. Cylindrical, conical, convex and concave, non-circular springs and elastic elements .

4. Features of WDW-TH series microcomputer-controlled locomotive spring lateral stiffness testing machine :

1. The whole machine is composed of vertical (radial) system, horizontal system, measurement and control system, safety protection system, etc.

2. Precision non-clearance ball screw, high rigidity and high stability load frame. The frame size can be customized.

3. Various control methods such as automatic load holding, stress and strain control, cycle control and self-programming control.

4. High-precision dynamometer, wide linearity, good stability, to ensure the accuracy of load measurement.

5. High-speed, low-vibration, maintenance-free, silent AC servo motor drive system.

6. Built-in Ethernet interface; convenient hand-held controller, stop and go function; flexible operation, free switching.

7. The circuit board adopts photoelectric isolation design with strong anti-interference ability.

8. Wide testing speed, pressure testing machine can be selected arbitrarily within 0.001~500mm/min. (Customizable high speed 0.001- 1 000mm/min)

9. The database adopts ACCESS format, which can carry out network database communication and management;

10. All-digital closed-loop, multi-channel, multi-function, easy-to-operate measurement and control software; a variety of test methods and standards (ASTM, ISO, DIN, EN, BS, etc.) are available in the database.

11. Automatic control of test process, real-time control and display of test force, peak value, deformation, displacement and test curve, full keyboard input operation and intelligent setting system of control mode; arbitrary setting of control mode, no impact, smooth switching , loading and unloading Steady .

12. Process reproduction, data re-analysis, curve enlargement, comparison and traversal.

13. The test curve can choose the coordinate axis arbitrarily, can zoom in and zoom out freely; multiple curves can be displayed at the same time, and the required coordinates can be set, such as: load-time, load-displacement, stress-strain, etc., full-scale self-adjustment.

14. Flexible Excel or Word report format, can choose to specify, sort, separate, merge, multiple types of output.

15. Modular and open programming to meet individual requirements. With prompt and wizard functions.

16. Automatic return after the test, intelligent, efficient and fast.

17. The multiple protection functions: overload test force; overcurrent, overvoltage protection; when the sample is broken security; Guide protection operation prompt; test ends the automatic protection .

18. The computer and the measurement and control system are integrated and placed in a standard cabinet.

5. Important parameters of WDW-TH series microcomputer-controlled locomotive spring lateral stiffness testing machine :

Device model: WDW-TH200/40, WDW-TH300/50

1. Spring vertical load system:

1. vertical to the maximum test force: 2 00kN , 300kN;

2. Effective measuring range of test force: 2 %-100% or 0.4 %-100%

3. Test force accuracy : ≤± 1 % or ±0.5%

4. Test test force resolution : . 1 / ± 300000F.S (full resolution change)

5. Vertical compression space : 0- 800mm

6. Effective test span : 610mm

7. The crosshead speed : 0.0 . 5 ~ . 3 00mm / min; (stepless)

8. Force control rate adjustment range : 0.005~5%FS/S

9. Relative error of force control rate : within ± 1 % of the set value or within ± 0.5%;

10. Deformation rate adjustment range : 0.02~5%FS/S

11. Vertical displacement resolution : 0.01mm

12. Vertical load motor power : 5kW

13. Upper pressure plate : Φ450mm

14. T-type workbench (WL) : 550x550mm

2) Spring transverse load system

1. The lateral most large test force : ± 40kN , ± 50kN

2. Effective measuring range of test force: 2 %-100% or 0.4 %-100%

3. Test force accuracy : ≤± 1 % or ±0.5%

4. Test test force resolution : . 1 / ± 300000F.S (full resolution change)

5. Transverse displacement stroke : 0 ~±100mm can be expanded

6. traverse rates : 0.0 2 ~ 2 00mm / min

7. Force control rate adjustment range 0.005~5%FS/S

8. Relative error of force control rate : within ± 1 % of the set value or within ± 0.5%

9. Deformation rate adjustment range : 0.02~5%FS/S

10. The lateral displacement resolution : 0.01mm

11. Transverse motor power : 0.75kW

Three) Spring transverse stiffness system load frame

1. Frame size LWH: 1360×1670×2860mm

2. Total power : 6.0kW

3. Whole machine weight: 2800kg, 3100kg

4. Control cabinet size (LWH) : 660×720×1850mm