1. Product overview

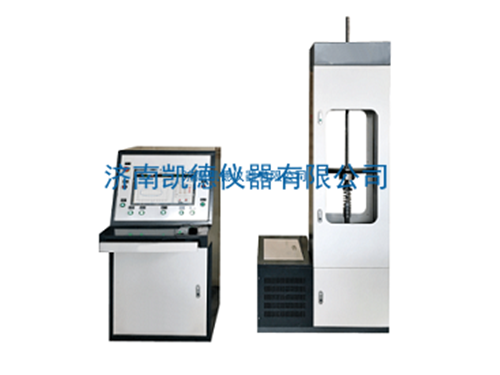

1. SXW-300/ 500 / 600/ 1000 microcomputer controlled steel strand slack testing machine in the design process absorbs and draws on the design concept and structural characteristics of the famous foreign slack testing machine company, and according to the relevant countries of the rebar slack test developed from the standard, dedicated to steel, galvanized steel and other materials rebar relaxation test for steel wire, galvanized steel wire, twisted steel manufacturing , quality control unit, research institutes and other buildings . 2. SXW-300/ 500 /600/1000 microcomputer-controlled steel strand relaxation tester is mainly used for the relaxation test of steel stranded wire, and can detect the uniaxial tensile relaxation strength of steel stranded wire and other metal wires. It can be widely used in quality inspection departments, construction units, steel strands and steel bars production enterprises, and is a new type of test equipment for modern building mechanics tests. 3. SXW-300/ 500 /600/1000 type microcomputer controlled steel strand slack testing machine host and auxiliary equipment, beautiful appearance, convenient operation, stable and reliable performance. The computer system controls the rotation of the servo motor through the servo controller and the speed control system. After deceleration by the deceleration system, the relaxation mechanical performance test of the sample is completed. It has no pollution, low noise, high efficiency, and has a very wide speed control range and beam movement. Distance has very broad application prospects. This machine is widely used in the inspection and analysis of metal materials in construction and building materials, aerospace, machinery manufacturing and other industries. It is an ideal testing equipment for quality inspection departments. 2. Features

1. Main functions 1) Smooth steel wire, scored steel wire, die-drawn steel wire, epoxy resin steel wire, prestressed steel wire, unbonded prestressed steel wire, galvanized steel wire Wire, metal materials, tensile stress relaxation characteristics testing and research. 2) Galvanized steel strand/epoxy resin-coated steel strand: external prestressing projects such as bridge tie rods, stay cables, load-bearing cables, stay cables, reinforcing cores, overhead power transmission ground cables, highway blocking cables, building structural cables, etc. . 3) PCB prestressed concrete steel bars: prestressed concrete round steel bars, spiral channel steel bars, spiral rib steel bars, ribbed steel bars; CRB650/CRB800/CRB970 cold rolled ribbed steel bars, concrete centrifuge tube piles, Prestressed components such as electric poles, viaduct piers, railway sleepers, etc.

2. Main test 1 ) Initial test force, initial test force retention, zero time to maintain initial total strain, constant gauge length, continuous recording of test force and temperature, regular recording of test force and temperature, monitoring of initial total strain, gauge length, and relaxation rate , Relaxation characteristic curve (residual test force-temperature, force-relaxation rate, force-displacement deformation, etc.), linear regression analysis, data calculation. 2) Isothermal stress relaxation test is to keep the sample at a certain length (L0+△L0) at a given temperature (20℃±2℃), start from the initial force F0, and measure the change of force on the sample; 3) Isothermal stress Relaxation test (maximum stress, given temperature, initial force, loss force, original gauge length 1000/steel strand lay length multiples, gauge length elongation, extensometer, 20% F0~80% F0 continuous loading, uniform rate loading, Three/multiple uniform stages, 80% F0~100% F0 continuous loading, constant, strain maintenance, strain change, force value recording frequency, force measurement resolution, extensometer resolution); 4) Isothermal stress relaxation test time (Start time, given time, interval time of recording force, continuous recording, relaxation time ≥120h/1000h, extrapolation);

3. According to the standard 1) GB/T10120-2013 "Metal Material Tensile Stress Relaxation Test Method" 2) GB/T5224-2014 "Steel Wire for Prestressed Concrete" 3) GB/T5223.3-2005 "Prestressed Concrete Steel bars" 4) GB/T21839-2008 "Test methods of steel for prestressed concrete" 5) ISO 15630-3:2002 "Test methods for steel for prestressed concrete and steel for prestressed concrete Part 3: Prestressed steel English version"; 6) EN10391:2003 "Metal Material Tensile Stress Relaxation Test Part 1: Test Procedure" 7) ASTM E328-"Test Method for Stress Relaxation of Materials and Structures"; 8) American Standard ASTM A416, ASTM A882/A882M -91; and other related foreign standards.

4. Main features 1 ) Horizontal four-column, high rigidity and high stability load frame. 2) Multiple control methods such as automatic holding, stress and strain control, repeated cycle control, and self-programming control. 3) High-precision dynamic and static dynamometer, wide linearity, good stability, and guarantee test accuracy. 4) High-speed, low-vibration, maintenance-free, silent AC servo motor drive system. 5) Precise temperature control, real-time follow. 6 ) The circuit board adopts photoelectric isolation design with strong anti-interference ability. 7 ) There are a variety of specifications of steel strands, PC steel rods, and metal material test fixtures for selection of pressure testing machines. 8 ) Wide testing speed, pressure testing machine can be selected arbitrarily within 0.001~150mm/min. 9 ) All-digital closed-loop, multi-channel, multi-function, easy-to-operate WANCE-test measurement and control software; a variety of test methods and standards (ASTM, ISO, DIN, JIS, EN, BS, etc.) are available in the database; test data is saved in real time , Query, call; 10) automatic control of the test process, test force, stress, deformation, full closed loop control, display, full keyboard input operation and control mode intelligent setting system; control mode can be set arbitrarily, no impact, smooth switching, loading , Unloading smoothly. 11) Arbitrary setting of loading rate, constant load and constant displacement control. 12)

Automatically obtain the stress relaxation performance (such as stress relaxation rate, relaxation stress, relaxation rate, etc.) and test curves of the specimen. 13) Data calculation: Test ≥100 hours, calculate 1000 hours of stress relaxation performance, calculation methods have double logarithmic and single logarithmic options, the calculated data have all data and characteristic time points corresponding data options; 14) Real-time drawing of remaining test force -Temperature, force-relaxation rate, force-displacement deformation and other curves; the test curve can be arbitrarily selected the coordinate axis of the pressure testing machine, and can be zoomed in and out freely; the required coordinates can be set, and the full degree can be adjusted automatically. 15) Can re-read the completed test, simulation reproduction, data re-analysis, multi-curve superposition, comparison and traversal. 16) Modular, open programming; test conditions (sample environment, test conditions) can be self-programmed; add at any time. Meet individual requirements. 17) Flexible Excel and Word report formats, default format and self-edited format; multiple sorts, multiple types of output. 18) Load digital calibration function, prompt and guide function. 19) Multiple protection functions: overload, overcurrent, and overvoltage protection; safety protection when the sample is broken and the end of the test.

Third, the main specification parameters

Serial number |

Project Description |

SXW- 300 |

SXW-5 00 |

SXW-6 00 |

SXW-1000 |

|

1 |

Maximum test force |

300kN |

5 00kN |

6 00kN |

10 00kN |

|

2 |

Test force measurement range |

0.4%~100%FS, no files in the whole process |

||||

3 |

Test force accuracy |

≤±0.5% |

||||

4 |

Test power resolution |

1/±500000F.S (The resolution remains unchanged throughout the process) |

||||

5 |

Adjust movement speed |

0.001~150mm/min |

||||

6 |

Load loading rate |

100-5000N/S arbitrary setting |

||||

7 |

Deformation measurement range |

0.2%-100%FS |

||||

8 |

Deformation measurement resolution |

0.001mm |

||||

9 |

Specimen gauge length |

The gauge length of the sample ≥ 60 times the nominal diameter of the sample |

||||

10 |

Stretching screw stroke |

0-300mm |

||||

11 |

Initial load application |

Automatically apply 70% breaking load or 80% breaking load / self-settable |

||||

12 |

Loader |

Full digital closed loop; automatic loading, holding, and automatic recording at a constant speed |

||||

13 |

Nominal size of steel strand |

Φ9.5 . 3 ; Φ11.10; Φ12.70; Φ15.24mm ; Phi] l . 7 . . 8 mm; [Phi] 2 . 1 . . 8 mm |

||||

14 |

Scalable sample |

Stress relaxation test of prestressed steel wire, prestressed steel rod and metal materials. |

||||

14 |

Load frame |

Horizontal structure; four columns, high rigidity, high stability |

||||

15 |

voltage |

~380V±10% 50Hz (reliable grounding is required) |

||||

4. Microcomputer-controlled steel strand slack testing machine system configuration

1. Test machine host 1 set

1) Servo motor 1 set

2) 1 set of governor

3) 1 load sensor

4) 1 set of deceleration system

2. 1 set of fully digital control system

3. 1 set of high-speed capture card

4. One set of control software based on Windows system

5. 1 set of random tools

6. Lenovo computer (LCD screen) 1

7. 1 inkjet printer

8. Technical data (instructions, certificates, packing list) 1 set