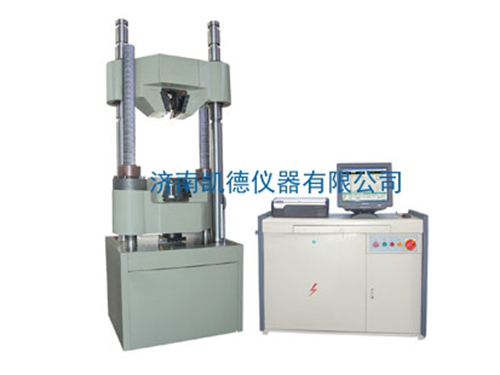

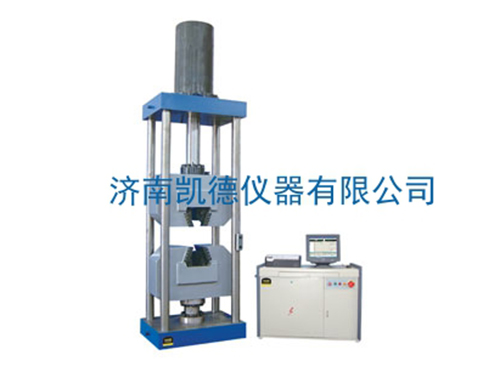

Product category: WAW cylinder under-mounted model—BI model

Product name: Microcomputer controlled electro-hydraulic servo universal testing machine—WAW-BI cylinder under-mounted series

Product model: WAW-600BI/1000BI(600-1000kN)

product manual:

1. Functions and features:

1. WAW-BI series microcomputer-controlled electro-hydraulic servo universal testing machine. The testing machine is mainly used for tensile, compression, bending, and shearing tests of metal materials. It adds simple accessories and devices, and can also perform tests on cement, concrete, etc. test.

2. The testing machine uses a microcomputer to control a high-precision electro-hydraulic servo valve and drives a precision hydraulic cylinder to realize automatic control of multiple modes such as constant rate testing force, constant rate displacement, and constant rate deformation, and complete the stretching and compression of the sample The flexural and flexural test meets the requirements of the national standard GB/T228-2008 "Metallic Material Tensile Test Method at Room Temperature". Adding accessories can complete the test requirements of other various materials.

3. The main machine of the testing machine adopts the hydraulic cylinder under-mounted type: the tensile space is located above the main machine, and the compression and bending test space is located under the main machine between the lower beam and the workbench. The lower beam is raised and lowered by a motor through a reducer, a chain drive mechanism, and a screw. Vice drive. The hydraulic cylinder is in the lower part of the testing machine, and the piston is pushed up under the action of hydraulic pressure, which can realize the compression, bending and shear test of the sample; the upper and lower jaw seats are fully open structure, which is convenient to clamp the sample and has good stability. . The structural design is reasonable, simple, stable, reliable, and easy to maintain. The hydraulic servo loading system ensures high precision, high efficiency, low noise, and fast response, and realizes automatic control of loading and reversing of the test.

4. Microcomputer control and processing system:

4.1 Electro-hydraulic servo control system: accurately complete the setting of test parameters during the test process, automatic control of the test process, data acquisition, processing, analysis, storage and display (test data includes: upper and lower yield points, tensile strength, breaking strength, Elastic modulus, elongation at each point, non-proportional elongation, etc.). In addition to the basic closed-loop control of test force, specimen deformation, piston displacement and test progress, and constant velocity stress, constant velocity strain, constant velocity test force, constant velocity displacement, test force retention, and displacement retention control functions, it also With convenient and quick open loop control function.

4.2 Screen display function of test force, peak value, sample deformation, piston displacement, test curve, full keyboard input operation and intelligent setting of control mode expert system, which realizes arbitrary setting of control mode and smooth switching between various control modes. Make the system have the greatest flexibility. The loading and unloading is stable, the program can be controlled during the test, and the "shortcut" operation of the fixed program is also available, and the test speed can be flexibly adjusted by the mouse;

4.3 The test data can be automatically collected and processed according to the requirements of national standards such as GB228-2008 "Metal Tensile Test Method for Room Temperature Materials". (There are a variety of test methods and standards in the data board, which can complete the experiment of a variety of materials) The test process can simulate reproduction and re-analysis of test data, test curve amplification, comparison, and traversal. The test curve can choose the coordinate axis arbitrarily, and can zoom in and out freely;

4.4 Test software based on WindowsXP operating system, amplifier zero adjustment, sensor calibration adopts a combination of reliable hardware support and software support to make the quality more perfect; it can implement sub-authority management for users, and has multiple graphic display windows and unit conversion functions ;

4.5 The test data is managed in a database, and network database communication and management can be carried out;

4.6 The test machine has the ability to expand and update;

5. Protection function:

5.1 Oil cylinder limit protection;

5.2 Hydraulic system overload and overflow protection;

5.3 Test force overload protection;

5.4 Overcurrent and overvoltage protection;

5.5 Safety protection when the sample is broken;

5.6 Automatic protection at the end of the test.

6. The integrated design of oil source, control cabinet and computer desk constitutes a control cabinet, and the oil source, strong electric board and computer host are installed in the control cabinet. On the control counter are monitors and printers. This not only ensures the stability of the hydraulic system, but also has a good overall effect. The humanized appearance design of the control cabinet console is convenient for operation and novel appearance. The integrated oil source control cabinet can be used for electro-hydraulic servo universal testing machines with different tonnages from 600kN to 1000kN.

2. Specification parameter table

Serial number |

model |

WAW-600BI |

WAW-1000BI |

|

1 |

Maximum test kN |

600 |

1000 |

|

2 |

Test force measurement range |

2%—100%FS |

||

3 |

Test force indication accuracy |

±1% |

||

4 |

Test force resolution kN |

0.01kN |

||

5 |

Maximum stretching space mm (including piston stroke) |

650 |

700 |

|

6 |

Maximum compression space mm (including piston stroke) |

380 |

||

7 |

Piston stroke mm |

150 |

||

8 |

Maximum moving speed of piston mm/min |

70 |

50 |

|

9 |

Clamping diameter of round specimen mm |

Φ13-Φ40 |

Φ13-Φ40 |

|

10 |

Flat specimen clamping thickness mm |

0-15 |

||

11 |

Clamping width of flat specimen mm |

75 |

75 |

|

12 |

Upper and lower plate size mm |

Φ160 or 204×204 |

||

13 |

Bending test attachment mm |

Support roller spacing 450 |

||

14 |

Cutting sample diameter mm |

Φ10 (optional) |

||

15 |

sensor |

Oil pressure sensor |

||

16 |

Display method |

Microcomputer screen display |

||

17 |

Clamping method |

Automatic clamping |

||

18 |

Oil pump motor power kW |

1.1 |

||

19 |

Power of beam moving motor kW |

0.75 |

||

20 |

Control cabinet size mm |

600×500×1300 |

||

twenty one |

Host size mm |

820×710×2100 |

900×710×2200 |

|

twenty two |

Host weight kg |

2500 |

3200 |

|

twenty three |

Host structure |

4 column 2 screw |

||

twenty four |

servo valve |

Domestic or Italian Athos or American MOOG |

||

25 |

Pump set |

Domestic pump set or Japan Fujitsu pump set |

||