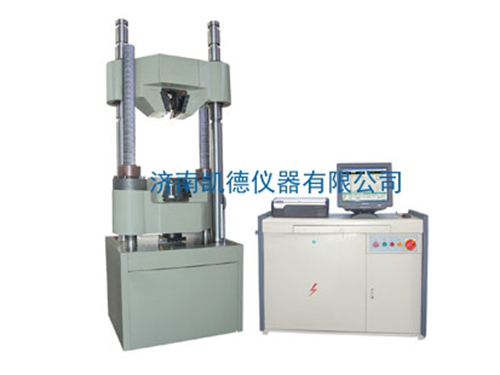

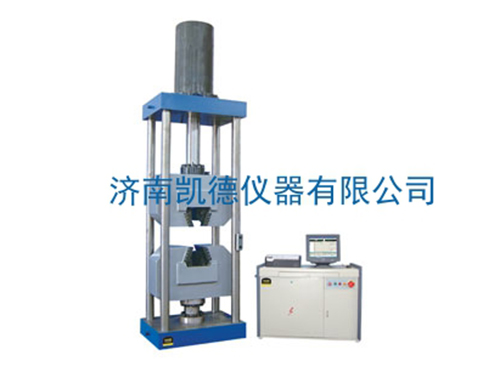

Product category: WAW cylinder under-mounted model—G model

Product name: Microcomputer controlled electro-hydraulic servoUniversal testing machine— WAW cylinder under-mounted series

Product model: WAW-300G/600G/1000G/2000G(300-2000kN)

product manual:

1. Functions and features:

1. Function:

WAW-G series microcomputer-controlled electro-hydraulic servo universal testing machine adopts an under-cylinder, four-column main engine, which is mainly used for metal and non-metal tensile, compression, bending and shear tests. It is suitable for metallurgy, construction, light industry, aviation, aerospace, materials, colleges and universities, research institutes and other fields. The test operation and data processing meet the requirements of GB-T_228.1-2010 "Metallic Materials-Tensile Test-Part One-Room Temperature Test Method" and GBT16826-2008 "Electro-hydraulic Servo Universal Testing Machine".

2 , features:

2.1 Host:

2.1.1 The main engine of the microcomputer-controlled electro-hydraulic servo universal testing machine adopts the lower cylinder type, the tensile space is located above the main engine, and the compression and bending test space is located between the lower beam of the main engine and the workbench.

2.1.2 The sturdy four-column double screw structure design makes the whole machine rigid and extremely stable.

2.1.3 The movable crossbeam is designed with a unique clearance elimination mechanism, which avoids the test error caused by the movement of the B-type machine crossbeam after being stressed.

2.1.4 There is a 10mm sliding plate between the jaw and the jaw splint, which effectively extends the service life of the jaw splint.

2.1.5 The test space can be adjusted in sections according to the length of the sample, and the highest point is suitable for the use of peripheral equipment such as high-temperature furnaces.

2.1.6 The oil cylinder adopts gap seal, which not only improves the measurement accuracy but also increases the service life.

3. Transmission system:

The lower crossbeam of the microcomputer controlled electro-hydraulic servo universal testing machine is driven by a motor, a cycloid reducer, a sprocket, and a nut screw pair to realize the adjustment of the tension and compression space.

4. Integral hydraulic control system

4.1 Microcomputer controlled electro-hydraulic servo universal testing machine adopts imported high-pressure gear pump with low noise and stable pressure.

4.2 The integrated design of the power system and the console is convenient for operation and saves experiment space.

4.3 The surface is treated with plastic spraying, and the appearance is beautiful.

5. Control system

5.1 Four types of closed-loop control of test force, sample deformation, beam displacement and test progress are realized;

5.2 The data acquisition system consists of 4 high-precision 32-bit A/D conversion channels. The highest resolution is 1/500000, and the whole process is not divided into files;

5.3 Select original brand-name integrated devices such as BB, AD, Xilinx, etc., and fully digital design;

5.4 Comply with PCI bus standard, automatic identification and installation by microcomputer, to achieve "plug and test";

5.5 The electronic measurement system has no analog components such as potentiometers to ensure interchangeability and facilitate maintenance and replacement.

2. Technical parameters of microcomputer controlled electro-hydraulic servo universal testing machine:

Product number |

WAW-300G |

WAW-600G |

WAW-1000G |

WAW-2000G |

|

Maximum test force (kN) |

300 |

600 |

1000 |

2000 |

|

Test force measurement range |

2%-100% |

||||

6KN-300kN |

12KN-600kN |

20KN-1000kN |

40KN-2000kN |

||

Test force indication accuracy |

±1% |

||||

|

Displacement measurement Resolution |

0.01mm |

||||

|

Deformation measurement Precision |

±0.5% |

||||

Constant force, constant deformation, constant displacement control accuracy |

Set value When the set value ≥ 10% FS, within ±0.5% of the set value |

||||

|

Deformation rate control precision |

rate When the rate is ≥0.05%FS, it is within ±0.5% of the set value |

||||

|

Maximum stretch space |

800mm |

800mm |

850mm |

800mm |

|

|

Maximum compression space |

700mm |

700mm |

700mm |

700mm |

|

Clamping thickness of flat specimen |

0-15mm |

0-15mm |

0-40mm |

0-60mm |

|

Clamping diameter of round specimen |

φ6-φ26mm |

φ13-φ40mm |

φ13-φ60mm |

φ15-φ70mm |

|

|

Bending test Support roller spacing |

450 mm |

||||

Roll width |

140mm |

||||

Pivot diameter |

30mm |

||||

Piston stroke |

250mm |

||||

Clamping method |

Built-in hydraulic clamping |

||||

|

shape size |

Host mm |

990×600×2435 |

990×600×2453 |

1100×770×2490 |

1160×1100× 2600 |

Oil source |

1100×700×950mm |

||||

Total Weight |

2800kg |

3000kg |

4700kg |

8000kg |

|

Note: The above are standard configurations, and can be customized according to customer requirements.