This system is designed and manufactured in accordance with the latest national standard GB228.1-2010. It is suitable for WE dial and WEW screen display series 50kN-2000kN hydraulic universal testing machine based on the transformation and upgrading to WAW microcomputer control electro-hydraulic servo automatic control. Electronic measurement collects test data, automatically completes metal tensile test, automatically analyzes, prints reports and curves.

Modified standard configuration and use

1. Hardware part

1) Lenovo commercial computer for automatic control and data processing;

2) HP printer, used to print reports and curves;

3) PCI interface AD800 universal test card, used for electronic signal amplification and data acquisition;

4) Special UTB-P electric control box for PWM power amplification of proportional valve group;

5) Precision pressure sensor for measuring test force;

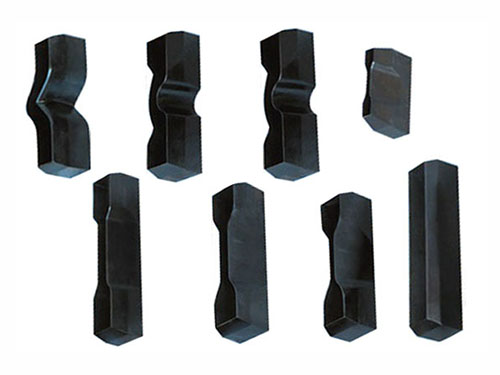

6) Electronic extensometer, used to measure deformation;

7) Photoelectric encoder for measuring the displacement of the beam;

8) Proportional speed control valve group; other installation accessories and connections;

2. Software part and purpose

1) UTC install software, provide AD800 driver;

2) VAC universal measurement and control drive for real-time data acquisition and closed-loop control;

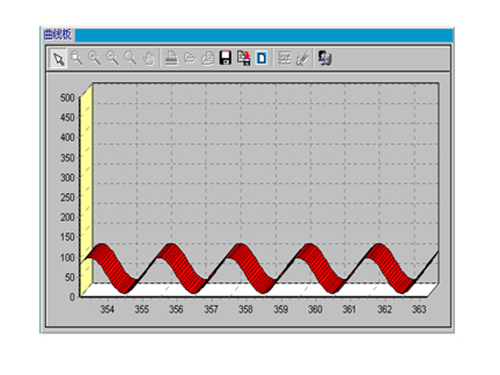

3) MaxTest software (WAWP standard version), used for dynamic display of test data and curves, automatic metal tensile test program control, material performance index analysis, report printing and database management.

4) The upgraded function of the test machine:

5) It has the screen display function of test force, force, peak value, sample deformation, piston displacement and test curve.

6) The data processing of the test can be completed according to the requirements of GB228.1-2010 "Metal Tensile Test Method for Room Temperature Materials". The original record value and report value of the test shall be revised according to the requirements of the standard GB228.

7) It has control functions such as constant velocity stress, constant velocity strain, constant velocity test force, constant velocity displacement, test force retention, and displacement retention.

8) Fm, Rel, Reh, Rp, Rt, Agt, Rm and other parameters can be automatically calculated in metal tensile test

9) It can output various curves of printing force-time, force-displacement, force-deformation, deformation-time, etc.

10) After the sample is broken, the moving beam will automatically stop; when the test force exceeds 2%-5% of the maximum test force of each gear, overload protection.

3. Service content

1) Modification of the main engine hydraulic system;

2) Installation, debugging and calibration of measurement and control electrical equipment;

3) Microcomputer software installation and initial setting;

4) Provide on-site personnel training.